What are the Types of Digital Twins - Levels and Applications

Digital twins have moved from futuristic buzzwords to practical tools reshaping industries across the globe. At their core, digital twins are virtual replicas of physical systems, objects, or processes. By combining real-time data, simulations, and machine learning, they allow businesses to monitor, analyze, and optimize everything from engines and factories to cities and even human bodies.

The concept has become so significant that questions like “What are the four types of digital twins?” or “What are the three levels of digital twin?” are now common among executives, engineers, and students alike. But digital twins are not a one-size-fits-all technology. They come in different types, dimensions, and applications depending on the industry and goal.

What Are the Types of Digital Twins?

When discussing the types of digital twins, it’s important to recognize that they are categorized based on their scope and functionality. Different frameworks exist, but one of the most widely accepted classifications divides them into four core types.

Product Twins

A product twin is the digital replica of a physical product, often used during design and development. Engineers can create a virtual model, test it in simulated environments, and identify flaws before producing a physical prototype. For example, automotive manufacturers build digital twins of cars to test aerodynamics or crash safety before the first car is built.

Process Twins

These twins simulate a manufacturing or operational process. Instead of modeling a single product, they replicate the entire production line or workflow. This helps companies identify inefficiencies, reduce downtime, and predict the impact of changes before implementing them.

System Twins

A system twin focuses on a larger, interconnected system — such as a factory, power grid, or supply chain. By analyzing data from various processes, businesses can monitor performance at scale and ensure everything works together seamlessly.

Human or Patient Twins

Increasingly relevant in healthcare, these twins simulate human organs, patients, or even entire populations. They are used in surgery planning, chronic disease monitoring, and public health modeling. While some argue these belong in the “application” category, many frameworks include them as a distinct type.

These four categories address the common question: “What are the four types of digital twins?” The answer typically includes product, process, system, and human/patient twins.

What Are the Three Levels of Digital Twin?

Alongside types, digital twins are also discussed in terms of levels or maturity stages. The question “What are the three levels of digital twin?” refers to how advanced the twin is in its functionality.

-

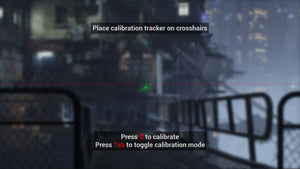

Descriptive Level – At this stage, the digital twin simply mirrors the physical object, providing visual or structural representation. It may be 2D or 3D, depending on the software used.

-

Predictive Level – Here, the twin uses real-time data and algorithms to forecast behavior or outcomes. For example, predicting when a jet engine might fail.

-

Prescriptive Level – The most advanced stage, where the twin doesn’t just predict problems but also suggests (or automatically takes) corrective action. For instance, a factory’s digital twin may adjust machine speed to prevent overheating.

These digital twin levels show how organizations can gradually adopt the technology — starting with descriptive models and evolving toward prescriptive, AI-driven twins.

Digital Twin Dimensions: 2D, 3D, 5D, and Beyond

Another way of classifying digital twins is by their dimensional complexity. This often raises questions such as “Is a digital twin 2D or 3D?” The truth is that both exist, depending on the context.

-

2D Digital Twins are often used in simpler applications like building floor plans or equipment schematics.

-

3D Digital Twins provide full spatial representations, which are crucial in industries like construction, aerospace, and healthcare.

More advanced frameworks talk about five dimensions of a digital twin, which include:

-

The physical object

-

The virtual model

-

The data connection between them

-

The analytics or algorithms that process the data

-

The services or applications that emerge from using the twin

An even newer concept is the 8D digital twin, which extends into additional dimensions such as lifecycle management, sustainability, and integration across organizations. While the terminology can vary, these concepts highlight how digital twins are evolving into more complex, multi-dimensional ecosystems.

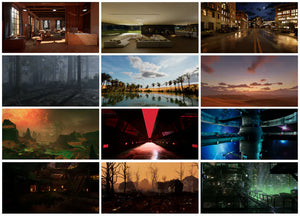

Digital Twin Examples Across Industries

Understanding digital twin examples helps to ground the theory in reality.

-

Automotive: Tesla is known for using digital twins of its vehicles, with real-time data from cars feeding into virtual models that predict maintenance needs.

-

Aerospace: Rolls-Royce uses digital twins of jet engines to monitor performance and optimize fuel efficiency.

-

Healthcare: Siemens Healthineers develops digital twins of hearts to test surgical procedures virtually.

-

Smart Cities: Singapore has created a digital twin of the entire city to manage urban planning, traffic flow, and environmental impact.

-

Retail: Amazon uses digital twins to optimize logistics, warehouse management, and even to simulate supply chain disruptions.

This also answers the question: “Does Amazon use digital twins?” Yes, extensively, particularly in logistics and fulfillment.

Interestingly, even Google Maps is sometimes considered a form of digital twin. When people ask, “Is Google Maps a digital twin?” the answer is nuanced. It functions as a digital twin of the Earth’s infrastructure — buildings, streets, and traffic patterns — though it is not a fully integrated, real-time, predictive twin like those used in manufacturing or healthcare.

Digital Twin Software and Engines

The rapid growth of this technology has been fueled by advanced digital twin software and platforms often referred to as digital twin engines. These engines process real-time data, run simulations, and deliver insights that businesses can act upon.

Examples include:

-

Siemens’ MindSphere – an IoT operating system supporting digital twin projects.

-

Dassault Systèmes’ 3DEXPERIENCE – widely used for product and system twins.

-

PTC’s ThingWorx – focused on industrial IoT and manufacturing.

-

Azure Digital Twins (Microsoft) – providing scalable cloud-based digital twin infrastructure.

Such platforms enable organizations to design, test, and operate digital twins without building everything from scratch. They are the backbone of nearly every digital twin project, serving industries from aerospace to retail.

Applications of Digital Twins

The application of digital twin technology spans nearly every industry, each adapting the concept to its unique needs.

In manufacturing, digital twins optimize production lines, reduce downtime, and ensure quality control. Factories can simulate equipment wear and tear before breakdowns happen, saving millions in maintenance costs.

In construction and architecture, building information models (BIM) enhanced by digital twins enable real-time monitoring of structures, predicting how materials will age or how buildings will respond to environmental stress.

In energy and utilities, power plants use digital twins to forecast demand, manage supply, and ensure safety. Wind farms, for example, model turbine performance to improve efficiency and reduce downtime.

In healthcare, as seen earlier, patient twins support personalized medicine and organ twins help in surgical planning.

In business operations, digital twins are increasingly used for customer journey mapping and logistics optimization. Companies replicate processes virtually to improve customer experiences or manage supply chain risks.

These examples demonstrate that the types of digital twins in business extend beyond traditional engineering to areas like marketing, retail, and finance.

Digital Twin vs Simulation

One common question is: “What’s the difference between a digital twin vs simulation?” While both involve virtual models, they are not the same.

A simulation is a static model used to test scenarios under specific conditions. For example, simulating airflow over a wing in a wind tunnel model. It’s typically limited to the situation it was designed for.

A digital twin, on the other hand, is a dynamic, data-driven model that evolves alongside its physical counterpart. It continuously ingests real-time data from sensors, IoT devices, and other sources, allowing it to update, adapt, and predict outcomes as conditions change.

Think of it this way: a simulation is like a photograph — capturing a moment in time. A digital twin is more like a live video feed — constantly updating and offering insights in real time.

Real-World Digital Twin Projects

Across industries, organizations are launching ambitious digital twin projects to transform their operations.

-

NASA pioneered the use of digital twins by creating replicas of spacecraft to monitor conditions remotely and troubleshoot problems in space.

-

BMW uses digital twins in its factories to simulate production processes, improving efficiency across thousands of manufacturing steps.

-

Singapore’s Smart Nation Initiative includes a full-scale digital twin of the city, providing real-time monitoring of traffic, utilities, and urban development.

-

Amazon, as noted earlier, applies digital twins in logistics and warehouse management, ensuring faster delivery and better inventory tracking.

These projects highlight the versatility of digital twins, proving they are not limited to any single sector.

Future of Digital Twins in Business

The future of digital twins will be defined by increasing complexity and deeper integration into decision-making. Businesses will no longer use digital twins as optional tools but as core engines of strategy.

Emerging areas include:

-

AI Integration: Enhancing digital twins with machine learning to create fully autonomous decision-making systems. This addresses the common query, “Is digital twin an AI?” Strictly speaking, a digital twin is not AI itself, but it often relies on AI for advanced analytics and predictions.

-

Sustainability Modeling: Digital twins will help organizations meet sustainability goals by simulating energy use, carbon emissions, and resource efficiency.

-

Cross-Industry Twins: As systems become more interconnected, digital twins of different sectors (transport, healthcare, retail) will integrate into larger ecosystems.

-

Immersive Interfaces: With AR/VR technologies, businesses will visualize and interact with their digital twins in immersive environments, making insights more accessible to decision-makers.

In this future, digital twin engines and software platforms will become as critical as ERP systems are today, guiding everything from daily operations to long-term innovation.

Conclusion

The types of digital twins go far beyond a single definition. From product, process, and system twins to patient models in healthcare, the technology adapts to the needs of every industry. The levels of digital twins — descriptive, predictive, and prescriptive — illustrate how organizations evolve in their adoption, while dimensions like 2D, 3D, 5D, and even 8D digital twins showcase their growing complexity.

Examples from Amazon, Google Maps, Rolls-Royce, and Siemens prove that digital twins are not hypothetical; they are practical tools transforming industries today. With applications in manufacturing, energy, healthcare, smart cities, and beyond, digital twins are emerging as the backbone of digital transformation.

Looking ahead, the integration of AI, sustainability initiatives, and immersive AR/VR interfaces will push digital twins into every corner of business and society. Companies that embrace this shift will be equipped not just to survive in the digital age but to thrive in it.

The time to act is now. Whether you’re launching your first digital twin project or scaling enterprise-wide initiatives, the opportunities are vast. By exploring advanced digital twin software and engines, businesses can unlock a future where decisions are smarter, operations are leaner, and outcomes are more predictable.

FAQs

Q1. What are the four types of digital twins?

The main four are product twins, process twins, system twins, and human/patient twins.

Q2. What are the three levels of digital twin?

Descriptive (basic representation), predictive (forecasting outcomes), and prescriptive (suggesting or taking corrective action).

Q3. What are digital twin examples?

Tesla cars, Rolls-Royce jet engines, Siemens cardiac models, Singapore’s smart city project, and Amazon’s logistics systems.

Q4. Is Google Maps a digital twin?

Yes, in a limited sense. It serves as a digital twin of Earth’s infrastructure, though it lacks the real-time predictive functions of industrial twins.

Q5. What are the 5 dimensions of digital twin?

Physical object, virtual model, data connection, analytics/algorithms, and resulting services.

Q6. What is an 8D digital twin?

An advanced model incorporating lifecycle management, sustainability, and cross-organizational integration beyond the traditional five dimensions.

Q7. Is digital twin an AI?

No. A digital twin is not AI itself, but it often integrates AI for predictive analytics and decision-making.

Q8. Is a digital twin 2D or 3D?

It can be both. Basic twins may be 2D, but most modern twins are 3D or higher-dimensional.

Q9. Does Amazon use digital twins?

Yes. Amazon applies digital twins extensively in logistics, warehouse management, and supply chain optimization.

Q10. What is the difference between a digital twin vs simulation?

A simulation is a static test of conditions, while a digital twin is a dynamic, real-time model that evolves alongside its physical counterpart.