LED Wall Virtual Production Maintenance Guide

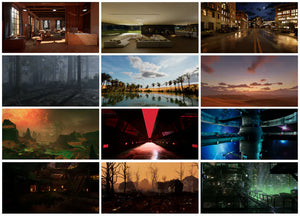

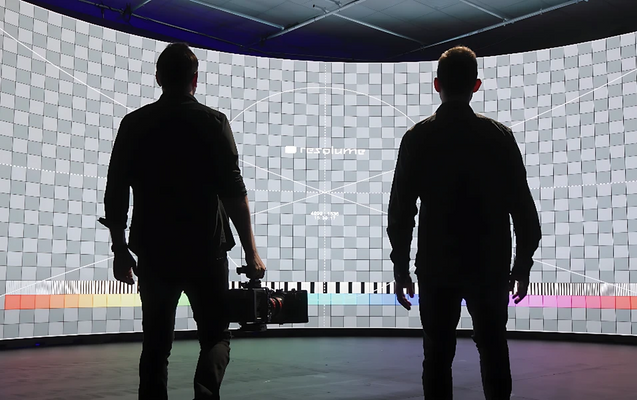

Modern film studios rely heavily on LED wall virtual production systems to create stunning visual effects and immersive environments. These sophisticated display systems have revolutionized how filmmakers approach cinematography, but like any advanced technology, they require proper maintenance to ensure optimal performance and longevity.

Proper LED maintenance isn't just about keeping your equipment running—it's about protecting your investment, maintaining image quality, and preventing costly downtime during critical production schedules. This guide provides essential maintenance protocols that production teams need to implement for their LED wall systems.

Understanding LED Wall Components and Maintenance Requirements

LED wall virtual production systems consist of multiple interconnected components that work together to create seamless visual experiences. Each component requires specific maintenance attention to ensure the entire system functions properly.

The LED panels themselves are the most visible component, featuring thousands of individual diodes that generate the images. These panels are sensitive to dust, moisture, and temperature fluctuations. Regular cleaning and environmental monitoring are essential for maintaining optimal brightness and color accuracy.

Control systems manage the data flow between computers and LED panels. These systems include processors, signal distributors, and calibration equipment that require regular software updates and hardware inspections. Proper ventilation and dust management are critical for these components.

Power distribution systems supply consistent electricity to all LED panels. These systems must be regularly inspected for loose connections, heat buildup, and power quality issues that could affect image stability or cause equipment damage.

Daily Maintenance Protocols for LED Wall Systems

Implementing daily maintenance routines helps identify potential issues before they become serious problems. Production teams should establish clear protocols that can be completed efficiently without disrupting filming schedules.

Begin each day with a visual inspection of all LED panels. Look for any dark pixels, color inconsistencies, or physical damage to the panel surfaces. Document any issues immediately and assess whether they require immediate attention or can be scheduled for later maintenance.

Check all cable connections between panels, processors, and control systems. Loose connections can cause signal loss, flickering, or complete panel failures. Ensure all cables are properly secured and show no signs of wear or damage.

Monitor system temperatures throughout the day. LED panels generate significant heat, and excessive temperatures can reduce lifespan and affect performance. Verify that cooling systems are functioning properly and air vents are clear of obstructions.

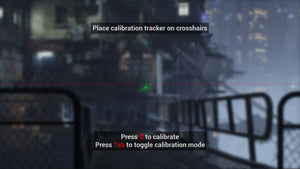

Test color calibration at the beginning of each production day. Even minor shifts in color accuracy can be noticeable on camera and require correction. Use standard test patterns to verify that all panels are displaying consistent colors and brightness levels.

Weekly Deep Maintenance Procedures

Weekly maintenance sessions allow for more thorough inspections and preventive care that can't be completed during daily operations. Schedule these sessions during production downtime to avoid interrupting filming schedules.

Clean LED panel surfaces using appropriate cleaning solutions and lint-free cloths. Remove dust, fingerprints, and any other contaminants that could affect image quality. Use only manufacturer-approved cleaning products to avoid damaging the panel coatings.

Inspect and clean cooling systems, including fans, air filters, and heat sinks. Dust buildup in cooling systems can cause overheating and reduce equipment lifespan. Replace air filters as needed and ensure all cooling fans are operating at proper speeds.

Check and tighten all electrical connections throughout the system. Vibrations from film equipment and normal use can cause connections to loosen over time. Use appropriate tools to ensure all connections are secure without over-tightening.

Update software systems and firmware as needed. LED wall systems rely on complex software for color management, calibration, and signal processing. Regular updates help maintain compatibility with new equipment and fix potential bugs.

Monthly Maintenance and Calibration Tasks

Monthly maintenance focuses on performance optimization and long-term system health. These procedures help maintain peak performance and extend equipment lifespan.

Perform complete color calibration using professional calibration equipment. This process ensures that all panels display accurate colors and consistent brightness levels. Document calibration results and compare them to previous measurements to identify any degradation trends.

Inspect structural mounting systems and hardware. LED panels are heavy and require robust mounting systems. Check for loose bolts, worn brackets, or any signs of stress in the mounting structure. Address any issues immediately to prevent panel damage or safety hazards.

Review and analyze system performance data. Modern LED wall systems generate detailed performance logs that can reveal patterns or trends that indicate developing problems. Regular analysis helps identify issues before they cause equipment failures.

Clean and inspect power distribution systems. Check for signs of overheating, corrosion, or wear in power connections. Measure voltage and current levels to ensure stable power delivery to all system components.

Troubleshooting Common LED Wall Issues

Production teams should be prepared to address common LED wall problems quickly to minimize downtime. Understanding typical issues and their solutions helps maintain production schedules.

Dead or stuck pixels are among the most common LED wall problems. Individual LED diodes can fail, creating dark spots or pixels that display incorrect colors. Most systems include pixel mapping software that can compensate for small numbers of failed pixels, but extensive pixel failure requires panel replacement.

Color inconsistencies between panels can develop over time due to aging or environmental factors. Regular calibration helps prevent these issues, but when they occur, recalibration or panel replacement may be necessary.

Signal loss or image artifacts often result from cable problems or processor issues. Check all connections and swap cables to isolate the problem. Processor overheating can also cause signal problems, so ensure adequate cooling.

Power-related issues can cause panels to flicker, dim, or fail completely. Check power connections and measure voltage levels to identify electrical problems. Uneven power distribution can cause performance variations across the LED wall.

Environmental Considerations for LED Wall Maintenance

The environment where LED walls operate significantly affects their maintenance requirements and lifespan. Controlling environmental factors helps reduce maintenance needs and extend equipment life.

Temperature control is critical for LED wall performance. High temperatures accelerate LED degradation and can cause immediate performance problems. Maintain ambient temperatures within manufacturer specifications and ensure adequate ventilation around all equipment.

Humidity levels should be controlled to prevent moisture damage to electronic components. Both high and low humidity can cause problems, so maintain levels within recommended ranges. Use dehumidifiers or humidifiers as needed.

Dust and particulate matter can accumulate on LED panels and cooling systems, affecting performance and causing overheating. Implement air filtration systems and regular cleaning schedules to minimize contamination.

Lighting conditions in the studio can affect LED wall performance and maintenance needs. Avoid direct sunlight on LED panels, as it can cause overheating and make maintenance inspections more difficult.

Safety Protocols for LED Wall Maintenance

Maintaining LED wall systems involves working with high-voltage electrical equipment and heavy panels. Following proper safety protocols protects maintenance personnel and prevents equipment damage.

Always power down systems before performing maintenance that requires physical contact with panels or electrical components. Use proper lockout/tagout procedures to prevent accidental power restoration during maintenance.

Use appropriate personal protective equipment, including safety glasses, gloves, and non-slip footwear. LED panels can have sharp edges, and electrical components pose shock hazards.

Follow proper lifting techniques and use appropriate equipment when handling LED panels. These panels are heavy and awkward to handle, requiring multiple people or mechanical assistance for safe removal and installation.

Maintain clear work areas and ensure adequate lighting for maintenance tasks. Good visibility helps prevent accidents and ensures thorough inspections.

Record Keeping and Documentation

Proper documentation helps track system performance, schedule maintenance, and identify trends that indicate developing problems. Maintain detailed records of all maintenance activities and system performance.

Create maintenance logs that record daily inspections, cleaning activities, and any issues identified. Include dates, personnel involved, and specific actions taken. These records help establish maintenance patterns and identify recurring problems.

Document all calibration results and performance measurements. Track changes over time to identify degradation trends and predict when major maintenance or replacement may be needed.

Keep detailed inventories of spare parts and replacement components. LED wall systems require specific parts that may have long lead times. Maintaining adequate spare parts inventory helps minimize downtime.

Maintain warranty and service contract documentation. Keep records of all warranty claims and service calls to ensure proper coverage and identify any patterns that might indicate systemic issues.

Cost-Effective Maintenance Strategies

Implementing cost-effective maintenance strategies helps control operating expenses while maintaining system performance. Balance maintenance costs with the cost of equipment replacement and production downtime.

Establish preventive maintenance schedules based on manufacturer recommendations and actual usage patterns. Regular maintenance costs less than emergency repairs and helps prevent major failures.

Train production staff to perform basic maintenance tasks. Simple tasks like cleaning and visual inspections can be performed by trained crew members, reducing the need for specialized service calls.

Negotiate service contracts with qualified technicians who have experience with LED wall systems. Regular service contracts often provide better value than per-incident service calls.

Consider the total cost of ownership when making maintenance decisions. Sometimes replacing aging components costs less than continuing to maintain them, especially if they're causing frequent problems.

Conclusion

Proper maintenance of LED wall virtual production systems is essential for reliable operation and long-term value. By implementing systematic daily, weekly, and monthly maintenance protocols, production teams can ensure optimal performance while minimizing costly downtime and equipment failures.

The key to successful LED wall maintenance lies in consistency, documentation, and proactive problem-solving. Regular inspections catch problems early, while proper cleaning and environmental control prevent many issues from developing. Training staff in basic maintenance procedures and maintaining detailed records helps optimize maintenance efficiency and costs.

Investing in proper maintenance pays dividends through extended equipment life, consistent performance, and reduced production interruptions. As LED wall technology continues to evolve, staying current with maintenance best practices ensures that production teams can maximize their investment in these powerful creative tools.

Frequently Asked Questions

Q: How often should LED wall panels be cleaned?

A: LED panels should be cleaned weekly during regular use, with daily spot cleaning as needed. High-usage environments may require more frequent cleaning to maintain optimal image quality and prevent dust buildup that can cause overheating.

Q: What cleaning products are safe for LED wall panels?

A: Use only manufacturer-approved cleaning solutions and lint-free cloths. Avoid harsh chemicals, abrasive materials, or excessive moisture that could damage panel coatings or seep into electronic components. Isopropyl alcohol solutions are typically safe for most LED panels.

Q: How long do LED wall panels typically last?

A: Professional LED wall panels typically last 50,000 to 100,000 hours of operation, depending on usage conditions and maintenance quality. Proper maintenance, temperature control, and environmental management can extend lifespan significantly.

Q: What are the signs that LED wall calibration is needed?

A: Signs include visible color differences between panels, brightness variations, or colors that don't match reference standards. Regular calibration should be performed monthly, with immediate recalibration if visual differences are noticeable.

Q: Can LED wall maintenance be performed during production?

A: Basic maintenance like visual inspections and temperature monitoring can be performed during production. However, cleaning, calibration, and electrical work should be scheduled during downtime to avoid disrupting filming and ensure safety.

Q: What spare parts should be kept on hand for LED wall systems?

A: Essential spare parts include replacement panels, power supplies, signal cables, and control processors. The specific inventory depends on system configuration and manufacturer recommendations, but having key components available minimizes downtime.

Q: How do environmental conditions affect LED wall maintenance needs?

A: High temperatures, humidity, and dust increase maintenance requirements. Controlled environments with proper ventilation and air filtration reduce cleaning frequency and extend component life. Extreme conditions may require daily maintenance checks.

Q: Who should perform LED wall maintenance?

A: Basic maintenance can be performed by trained production staff, while complex procedures require qualified technicians. Electrical work and calibration should only be performed by personnel with appropriate training and certification.