Digital Twins In Construction: The Future of Architecture

The world of construction is changing rapidly. From blueprint drawings to Building Information Modeling (BIM), the industry has always adapted to new technologies — but nothing is revolutionizing it as deeply as digital twins in construction. This cutting-edge concept is transforming how buildings are designed, built, and managed.

A digital twin is not just a model; it’s a living, breathing digital representation of a real-world building, system, or infrastructure. It continuously updates with data from sensors, Internet of Things (IoT) devices, and AI-powered systems, allowing architects, engineers, and builders to monitor and optimize the entire lifecycle of a project — from concept to demolition.

Today, digital twins in construction are becoming the foundation of smart architecture and data-driven decision-making, helping companies reduce costs, improve safety, and design more sustainable environments.

What Are Digital Twins in Construction?

In simple terms, a digital twin in construction is a virtual replica of a physical building or structure. This virtual model captures every detail of the building — from its design and construction materials to its energy systems and ongoing maintenance data.

Digital twins go beyond visualization. They combine real-time data with AI and machine learning algorithms to simulate performance, predict future outcomes, and optimize efficiency. For example, before pouring concrete, engineers can simulate stress tests or check energy consumption projections using the digital twin.

Unlike traditional modeling systems, digital twins are dynamic and intelligent. They evolve alongside the building, constantly updated with new data from on-site sensors and equipment.

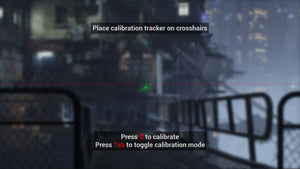

A typical digital twin architecture diagram includes the following layers:

-

Data Collection Layer – Gathers real-time information from sensors, IoT devices, and on-site cameras.

-

Integration Layer – Combines collected data into a centralized BIM (Building Information Modeling) environment.

-

Analytics and Simulation Layer – Uses AI, ML, and predictive analytics to identify trends and detect issues.

-

Visualization Layer – Allows stakeholders to view, interact with, and analyze the digital twin through dashboards or AR/VR tools.

This interconnected architecture enables constant collaboration between architects, engineers, and contractors — reducing communication gaps and preventing costly design flaws before they occur.

The Evolution: From BIM to Digital Twins

Many people confuse BIM (Building Information Modeling) with digital twins, but they are not the same. BIM was the first major leap toward virtual construction environments, allowing designers to create 3D representations of buildings. However, BIM is static. Once a building is constructed, the BIM model typically stops evolving.

Digital twins, on the other hand, take BIM to the next level. They extend the model into the operational phase, integrating real-time data to monitor the building’s performance throughout its entire lifecycle.

Think of BIM as the design phase and the digital twin as the life phase of the building. The BIM digital twin concept merges both — using BIM data as the foundation for the live, data-driven digital model.

This connection enables real-time energy tracking, automated maintenance alerts, and even disaster prevention simulations.

Benefits of Digital Twins in Construction

Benefits of Digital Twins in Construction

The benefits of digital twins in construction go far beyond visualization. They are transforming project management, design, safety, and sustainability across the entire industry.

Here are some of the most significant advantages:

1. Real-Time Monitoring and Control

With digital twins, construction managers can monitor the site remotely. IoT sensors collect live data about temperature, humidity, equipment status, and worker safety. This real-time insight ensures quicker responses and better quality control.

2. Predictive Maintenance

One of the most powerful aspects of digital twins is their predictive capabilities. The system can analyze data to forecast when a component — such as an HVAC system or elevator — might fail. This reduces downtime and extends the life of building assets.

3. Enhanced Collaboration

Digital twins serve as a single source of truth for everyone involved in the project — from architects to investors. With cloud integration, team members can access the same model simultaneously, eliminating communication gaps and project delays.

4. Cost and Time Efficiency

Early detection of design flaws or performance issues through simulations prevents expensive rework. The ability to visualize every stage before construction begins helps optimize resources and minimize waste.

5. Sustainability and Energy Efficiency

In a world focused on sustainability, digital twins allow architects to test different materials, energy systems, and layouts before construction. This ensures energy-efficient designs and supports carbon-neutral construction goals.

6. Improved Safety and Risk Management

By simulating various “what-if” scenarios, digital twins can predict potential safety hazards on-site — such as structural stress points or fire risk zones. These predictions help prevent accidents and ensure safer construction environments.

Digital Twins in Construction Examples

Digital twin technology is not just a futuristic idea — it’s already being implemented in some of the world’s most ambitious construction projects.

1. The Heathrow Airport Expansion (UK)

During the massive expansion project at Heathrow, engineers created digital twins of terminal areas and runways to simulate airside operations. These models helped optimize logistics, streamline maintenance schedules, and improve overall passenger flow efficiency.

2. Hong Kong-Zhuhai-Macao Bridge (China)

For one of the longest sea-crossing bridges in the world, digital twin technology was used to monitor structural integrity, stress distribution, and vibration in real-time. The data ensured long-term safety and maintenance efficiency.

3. Microsoft Redmond Campus (USA)

Microsoft’s headquarters redevelopment incorporated digital twins to track energy consumption, monitor air quality, and automate building systems. The result was a sustainable, smart workplace that dynamically adapts to employee needs.

4. City of Singapore – Virtual Singapore

Singapore’s government launched Virtual Singapore, a digital twin of the entire city. This urban-scale model helps planners simulate the effects of new buildings, traffic changes, and environmental shifts — a perfect example of digital twins in construction at a national level.

Case Study: Singapore’s Smart Nation Vision

When it comes to large-scale implementation, Singapore stands as a global pioneer in using digital twins in construction. The nation’s Virtual Singapore project is one of the world’s first fully integrated, city-wide digital twins — a 3D, data-rich model that reflects the entire city’s physical infrastructure and environmental dynamics.

How It Works

Virtual Singapore collects data from sensors, satellite imagery, drones, and BIM models to simulate everything from building energy usage to pedestrian flow. It allows city planners to test various “what-if” scenarios, such as:

-

How new skyscrapers affect wind patterns and sunlight exposure.

-

The impact of traffic congestion on nearby structures.

-

Flood simulation and water drainage efficiency.

The Outcome

This system helps Singapore achieve smarter urban planning, energy-efficient architecture, and better emergency response management. It’s not just a visualization tool; it’s a living ecosystem that continues to evolve with the city — showing how digital twin construction can transform entire nations.

Digital Twins in Construction Jobs: Shaping the Future Workforce

As digital twins gain momentum, they are also reshaping the construction job market. The rise of data-driven building design and maintenance has created an entirely new class of professionals who blend technical engineering expertise with digital intelligence.

Here are some emerging digital twin jobs in construction:

-

Digital Twin Engineer – Designs, integrates, and manages the digital twin model, ensuring real-time synchronization with the physical structure.

-

BIM Data Analyst – Analyzes data generated from BIM and IoT systems to extract actionable insights.

-

IoT Integration Specialist – Connects sensors and devices to feed live data into the twin model.

-

Construction Data Scientist – Uses machine learning to predict performance outcomes and optimize energy efficiency.

-

Smart Building Systems Operator – Manages the operational side of buildings using real-time data from the digital twin.

These roles highlight the growing intersection between architecture, engineering, data science, and AI — redefining what it means to work in the construction industry.

How Digital Technology Is Used in Construction

The digital transformation of construction is much broader than just digital twins. Several interconnected technologies power the smart construction ecosystem:

1. Building Information Modeling (BIM)

BIM serves as the foundation for most digital twin projects. It provides the structural and design data upon which live sensor data can be layered.

2. Internet of Things (IoT)

IoT sensors placed on equipment, walls, and materials provide continuous streams of data such as vibration levels, humidity, or energy use. These feed into the digital twin for real-time updates.

3. Artificial Intelligence (AI) and Machine Learning (ML)

AI enables predictive maintenance, design optimization, and automated risk detection. ML algorithms learn from past performance data to improve future designs.

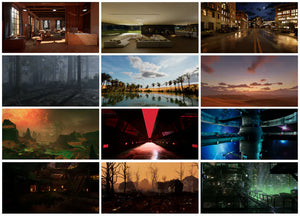

4. Augmented and Virtual Reality (AR/VR)

AR/VR technologies allow engineers and clients to walk through the virtual building before it’s constructed. This improves decision-making and design accuracy.

5. Cloud Computing

Cloud platforms allow collaboration and storage of massive data sets. They make it possible for stakeholders around the world to access and update the digital twin in real-time.

Together, these technologies enable smarter, faster, and safer construction projects, making digital twins the centerpiece of the modern construction ecosystem.

The Future of Digital Twins in Architecture

As smart cities and sustainable design become global priorities, the use of digital twins in architecture will continue to grow. Future buildings will be more than static structures — they’ll be intelligent, adaptive ecosystems that respond to human behavior and environmental change.

Trends Driving the Future

-

AI-powered predictive twins that can make autonomous decisions.

-

Integration with robotics for automated construction monitoring.

-

Blockchain-backed data security for digital twin networks.

-

Immersive 3D visualization through extended reality (XR).

Soon, digital twins won’t just mirror the physical world — they’ll enhance it by creating feedback loops between design, construction, and daily operations.

FAQs About Digital Twins in Construction

Is AutoCAD a digital twin?

No, AutoCAD is a design and drafting tool used for creating 2D and 3D models. A digital twin, however, is a dynamic virtual model connected to real-time data from the physical building.

How is digital technology used in construction?

Digital technology enhances construction through BIM modeling, IoT sensors, AI simulations, and AR/VR visualization. These tools collectively improve project accuracy, safety, and efficiency.

What is a building digital twin?

A building digital twin is a virtual model of a physical structure that continuously updates using live data from sensors, allowing real-time performance tracking and predictive maintenance.

What is a BIM digital twin?

A BIM digital twin merges BIM design data with IoT-driven live information. It enables full lifecycle management — from design to demolition — in a single, intelligent system.

Is a digital twin 2D or 3D?

A digital twin is typically 3D, but it goes beyond geometry to include time, performance, and behavioral data, creating a multi-dimensional view of the building.

Which software is used for digital twins?

Popular digital twin platforms include Autodesk Tandem, Siemens NX, PTC ThingWorx, Bentley iTwin, and Dassault Systèmes 3DEXPERIENCE.

What are the 4 levels of digital twins?

-

Descriptive Twin – A static model of the structure.

-

Informative Twin – Adds real-time data for monitoring.

-

Predictive Twin – Uses AI to forecast performance.

-

Autonomous Twin – Self-learning, capable of decision-making.

Is BIM 2D or 3D?

BIM is inherently 3D, but it can extend to 4D (time), 5D (cost), and even 7D (sustainability) depending on project requirements.

Is digital twin an AI tool?

Not exactly. A digital twin uses AI as part of its analytical process, but it is a broader ecosystem that combines BIM, IoT, and cloud computing technologies.

Conclusion: Building Smarter, Building the Future

The rise of digital twins in construction marks a new era in architectural innovation. No longer limited to static blueprints or 3D renders, buildings are now living digital ecosystems that evolve, adapt, and optimize themselves in real-time.

From improved design accuracy and reduced costs to sustainable energy management and predictive maintenance — digital twins offer unmatched value across every phase of a building’s lifecycle.

As the construction industry moves toward automation, AI, and smart infrastructure, adopting digital twin technology is no longer optional — it’s essential. Those who embrace this transformation today will lead the future of architecture and construction tomorrow.

Ready to explore how digital twins can revolutionize your construction projects? Contact us today to learn how we can help you implement smart, data-driven solutions for sustainable construction.