What is Virtual Prototyping? – How it Works and Benefits

In today’s fast-paced innovation landscape, virtual prototyping has emerged as a game-changer for engineers, designers, and manufacturers. Instead of building multiple physical models, companies now simulate their products in a 3D virtual environment, testing performance, ergonomics, and functionality before production begins.

This approach saves time, cost, and materials—and it’s reshaping industries from automotive engineering to furniture and fashion design. Let’s explore what virtual prototyping is, how it works, and why it’s transforming modern product development.

What Is Meant by Virtual Prototyping?

Virtual prototyping refers to the use of computer-aided design (CAD) and simulation software to create digital models of products. These virtual prototypes mimic real-world conditions—allowing designers to test, analyze, and refine their ideas without manufacturing a single part.

Unlike traditional prototyping, which involves physical fabrication, virtual prototyping allows you to:

-

Visualize your design in 3D

-

Simulate stress tests, thermal analysis, or aerodynamics

-

Identify design flaws early

-

Collaborate digitally across teams and departments

This technology forms a bridge between conceptualization and real-world testing—empowering businesses to bring better products to market faster.

Types of Virtual Prototyping Technology

Virtual prototyping can be categorized into several types depending on its purpose and technology used:

-

3D Virtual Prototyping

The most common type—used to create three-dimensional models that replicate form, texture, and movement. Tools like Autodesk Fusion 360 or SolidWorks enable realistic rendering and animation for detailed visualization. -

Functional Virtual Prototyping

Goes beyond visuals. Engineers use it to simulate mechanical, electrical, and fluid systems in real-time. It helps identify performance gaps before production. -

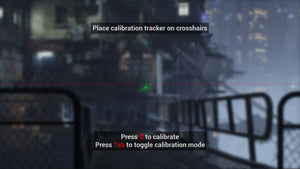

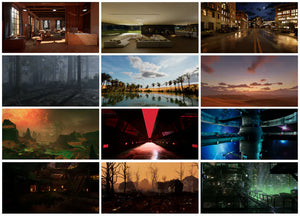

VR-Based Virtual Prototyping (Virtual Reality Prototyping)

Integrating virtual reality lets designers experience the product in immersive 3D environments. It’s widely used in automotive and aerospace industries, where spatial experience and ergonomics are crucial.

How Virtual Prototyping Works

Virtual prototyping software follows a structured process combining modeling, simulation, and validation.

-

Concept Design:

The product idea is visualized using CAD tools. Designers sketch geometry and define materials. -

3D Modeling:

Engineers convert the 2D sketches into 3D virtual models. These can be manipulated, rotated, and rendered for realistic viewing. -

Simulation and Testing:

The prototype undergoes performance tests through virtual simulation—checking load-bearing, motion, heat dissipation, or energy consumption. -

Optimization:

Designers make adjustments to improve performance. Machine learning algorithms in advanced software suggest enhancements automatically. -

Final Validation:

Once validated virtually, the product can move directly to physical prototyping or production—cutting down time by 50–70%.

Virtual Prototyping Software: Tools Leading the Future

Virtual prototyping software plays a critical role in this ecosystem. Here are some top tools used across industries:

-

ANSYS – Ideal for multiphysics simulations, widely used in aerospace and mechanical engineering.

-

Autodesk Inventor – Comprehensive design suite supporting 3D virtual prototyping.

-

CATIA by Dassault Systèmes – Popular in automotive virtual prototyping for high-precision modeling.

-

SolidWorks – A go-to for furniture and product designers due to its realistic rendering capabilities.

-

Synopsys Virtual Prototyping – Specialized for electronic systems and embedded software testing in high-tech industries.

These platforms enable cross-functional teams to collaborate efficiently, simulate real-world physics, and reduce the gap between digital design and physical production.

Applications of Virtual Prototyping Across Industries

Virtual prototyping isn’t limited to one field—it has become essential in various industries aiming to minimize costs and maximize performance.

1. Virtual Prototyping in Automotive Industry

Virtual prototyping for automotive design allows engineers to test vehicle components like engines, suspensions, and electrical systems virtually. Companies like BMW and Tesla use 3D simulation software to:

-

Analyze aerodynamics and safety performance.

-

Optimize battery efficiency for EVs.

-

Test interior ergonomics using VR-based simulation.

Virtual prototyping for EVs (Electric Vehicles) has become especially vital for thermal management and battery safety testing—long before cars hit the road.

2. Furniture Virtual Prototyping

Furniture virtual prototyping software helps designers visualize textures, fabrics, and shapes digitally before manufacturing.

Using 3D virtual prototyping, designers can:

-

Preview furniture in real environments (homes, offices).

-

Experiment with different materials and upholstery designs.

-

Reduce waste and production errors.

Many modern furniture companies are now embracing upholstery virtual prototyping tools to allow customers to customize products virtually—choosing colors, fabrics, and patterns online.

3. Virtual Prototyping for Fashion & Textiles

In the fashion industry, virtual prototyping technology is revolutionizing how designers create and test garments. Tools like CLO 3D and Browzwear let designers:

-

Simulate fabric drape and movement on virtual mannequins.

-

Reduce sample production waste.

-

Accelerate design cycles.

This virtual prototyping for fashion trend aligns perfectly with sustainability goals—enabling brands to minimize physical sampling and carbon footprint.

4. Virtual Prototyping for Electrical Machines

In electrical engineering, virtual prototyping software allows simulation of motors, generators, and circuits under real-world conditions.

Virtual prototyping electrical machines helps engineers:

-

Optimize electromagnetic designs.

-

Predict power losses and heat generation.

-

Integrate control algorithms seamlessly.

This is particularly important in high-tech industries like renewable energy and electric mobility, where precision and efficiency are key.

5. Virtual Prototyping in High-Tech and Electronics

For semiconductor and embedded systems, Synopsys virtual prototyping tools are among the most advanced. They enable developers to:

-

Create software prototypes before hardware exists.

-

Validate firmware and drivers early in the design cycle.

-

Shorten time-to-market for complex electronic systems.

In the high-tech sector, these tools reduce development cycles by months—helping companies stay ahead in competitive markets.

Benefits of Virtual Prototyping

The adoption of virtual prototyping technology has brought measurable benefits to every stage of the product lifecycle—from concept design to final manufacturing. Below are the key advantages that make it indispensable for modern industries.

1. Cost Reduction

Traditional prototyping requires multiple physical samples, each consuming materials, labor, and time. Virtual prototyping software eliminates the need for repeated physical models by simulating product performance in 3D.

Companies can save up to 60% in development costs while ensuring precision and quality before production begins.

2. Faster Time-to-Market

The ability to test, modify, and optimize virtually enables faster decision-making. Engineers can run real-time simulations and make design adjustments on the fly, drastically shortening product development cycles.

For industries like automotive and fashion, where market trends evolve rapidly, this speed provides a significant competitive edge.

3. Enhanced Collaboration

Cloud-based virtual prototyping tools allow cross-functional teams—designers, engineers, marketers, and clients—to work on the same model simultaneously.

This level of collaboration ensures transparency, immediate feedback, and faster design iterations.

4. Sustainability and Waste Reduction

By reducing the number of physical samples and tests, virtual prototyping helps minimize waste.

In furniture and fashion, this means fewer discarded materials, lower energy usage, and a smaller carbon footprint. The technology contributes directly to eco-friendly manufacturing.

5. Risk Mitigation

Virtual simulations allow you to identify design flaws or performance issues early in the process. Engineers can anticipate potential failures under different operating conditions—helping prevent costly recalls or design overhauls.

6. Customization and Innovation

In industries like upholstery and furniture, customers can personalize designs virtually before production.

Manufacturers use 3D virtual prototyping tools to show realistic previews of products, increasing customer satisfaction and confidence.

Real-World Examples of Virtual Prototyping

Let’s explore how different industries have successfully implemented virtual prototyping tools and software to revolutionize their workflows.

Automotive Industry: Tesla and BMW

Companies like Tesla use virtual prototyping for automotive design to test battery systems and energy efficiency. Using advanced simulation, they model vehicle aerodynamics, crash behavior, and noise reduction.

Similarly, BMW’s virtual vehicle platform allows engineers to simulate entire driving experiences—including lighting, sound, and ergonomics—long before the car is physically assembled.

Furniture Design: IKEA’s 3D Visualization

IKEA has integrated furniture virtual prototyping software to let customers visualize how sofas, tables, or chairs look in their own homes using Augmented Reality (AR).

By pairing virtual prototyping with AR, IKEA ensures a seamless bridge between design concept and user experience.

Fashion Industry: Nike & CLO 3D

Global brands like Nike and Adidas use virtual prototyping for fashion to visualize sportswear, simulate fabric stretch, and refine patterns virtually.

Using platforms like CLO 3D, designers can adjust colors, textures, and fits instantly—reducing physical samples and production lead time.

High-Tech Sector: Synopsys in Semiconductor Design

In the electronics industry, Synopsys virtual prototyping has become the gold standard for chip and embedded system development.

By enabling software development on virtual hardware, engineers can begin integration and debugging months before physical chips are available—reducing time-to-market significantly.

Electrical Machines: Siemens & ANSYS

Siemens uses virtual prototyping electrical machines simulation to optimize motor performance. Through ANSYS software, engineers test for heat distribution, electromagnetic interference, and vibration—helping them create more efficient and reliable machines for industrial use.

Virtual Prototyping Tools & Platforms Overview

Here’s a summary of popular tools used for 3D virtual prototyping and their industry focus:

|

Software |

Primary Use |

Industry Applications |

|

CATIA |

3D modeling & design |

Automotive, Aerospace |

|

SolidWorks |

Product & furniture design |

Manufacturing, Furniture |

|

CLO 3D |

Virtual garment simulation |

Fashion & Apparel |

|

ANSYS |

Engineering simulation |

Electrical, Mechanical |

|

Autodesk Fusion 360 |

CAD/CAM modeling |

General product design |

|

Synopsys |

Embedded software & electronics |

High-tech, Semiconductor |

|

Siemens NX |

Multi-discipline design |

Automotive, Aerospace |

Each tool offers unique capabilities—from real-time visualization to physical behavior simulation—depending on your product type and industry.

The Future of Virtual Prototyping Technology

As industries continue their digital transformation, virtual prototyping technology is set to evolve even further with integrations like:

-

Artificial Intelligence (AI) – Automating design optimizations and predicting performance outcomes.

-

Augmented & Virtual Reality (AR/VR) – Offering immersive design reviews and client presentations.

-

Cloud-Based Collaboration – Enabling remote, real-time teamwork for global design teams.

-

Digital Twins – Creating connected virtual representations of physical products to track performance post-launch.

By combining these technologies, businesses will move closer to zero-defect manufacturing and fully digital design ecosystems.

FAQs About Virtual Prototyping

What is meant by virtual prototyping?

Virtual prototyping is the process of creating and testing digital models of products using computer software before making physical prototypes. It allows designers to simulate, analyze, and improve product performance virtually.

What are the three types of prototyping?

The three main types are conceptual, functional, and virtual prototyping. Each focuses on different stages—from idea generation to testing the actual functionality.

Can a prototype be virtual?

Yes. A virtual prototype is a computer-generated model that mimics the behavior and performance of a real product using simulations.

What is virtual reality prototyping?

It combines VR technology with 3D modeling to let designers and engineers interact with digital prototypes in immersive virtual spaces—ideal for automotive, architecture, and product design.

What are the four kinds of prototyping?

They include throwaway, evolutionary, incremental, and extreme prototyping—with virtual prototyping often overlapping with evolutionary methods due to its iterative nature.

What is the most popular prototyping tool?

It depends on the industry. For general engineering, SolidWorks and Autodesk are most popular; for electronics, Synopsys leads; and for fashion, CLO 3D is the top choice.

Embracing the Virtual Design Revolution

Virtual prototyping is more than just a design trend—it’s the foundation of future innovation. Whether it’s automotive engineering, furniture design, or high-tech electronics, virtual prototyping enables faster, smarter, and more sustainable product development.

By adopting 3D virtual prototyping software and simulation tools, companies not only enhance creativity and efficiency but also drastically cut costs and lead times. The future of design lies in the digital-first approach, where imagination meets technology—and virtual prototypes bring ideas to life before a single piece is built.

Ready to integrate virtual prototyping into your workflow?

Empower your team with the latest design tools and start developing smarter, faster, and greener today. Get a Free Consultation on the best virtual prototyping software for your business.